Food

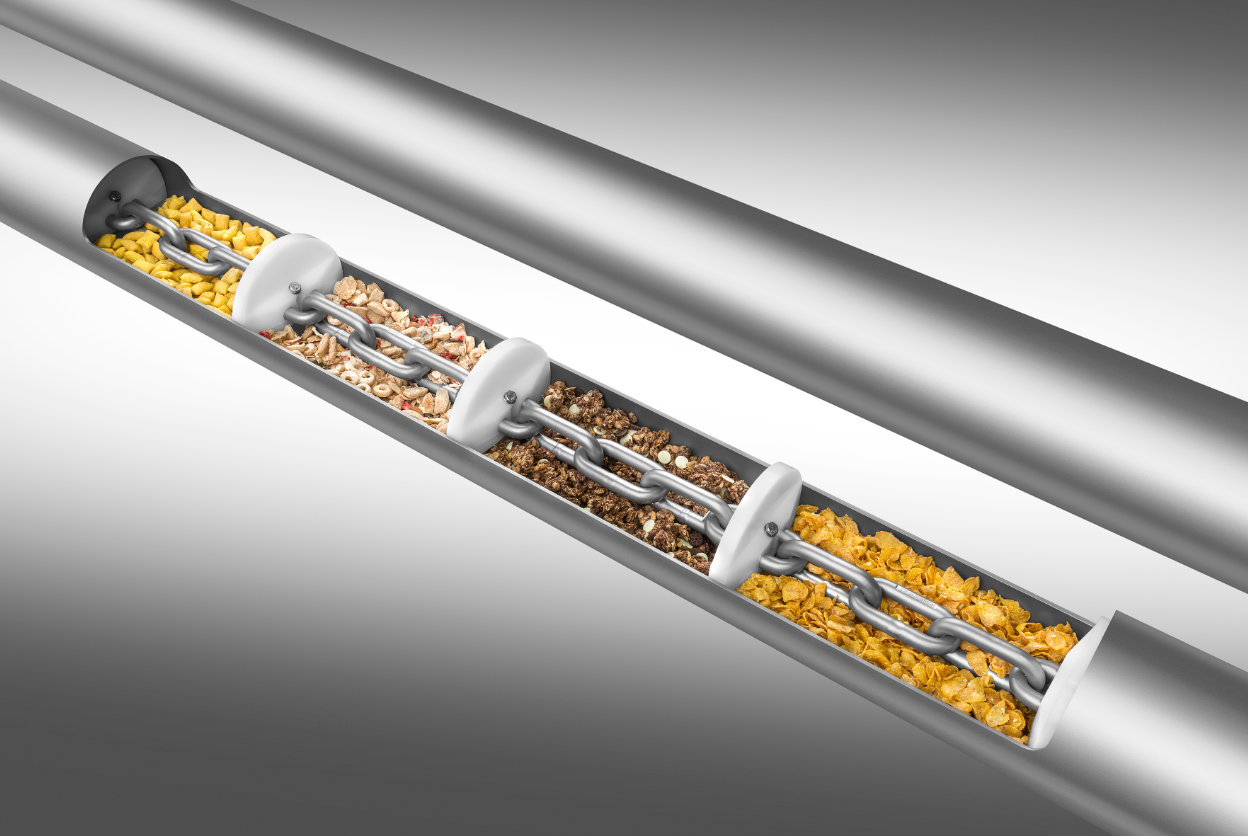

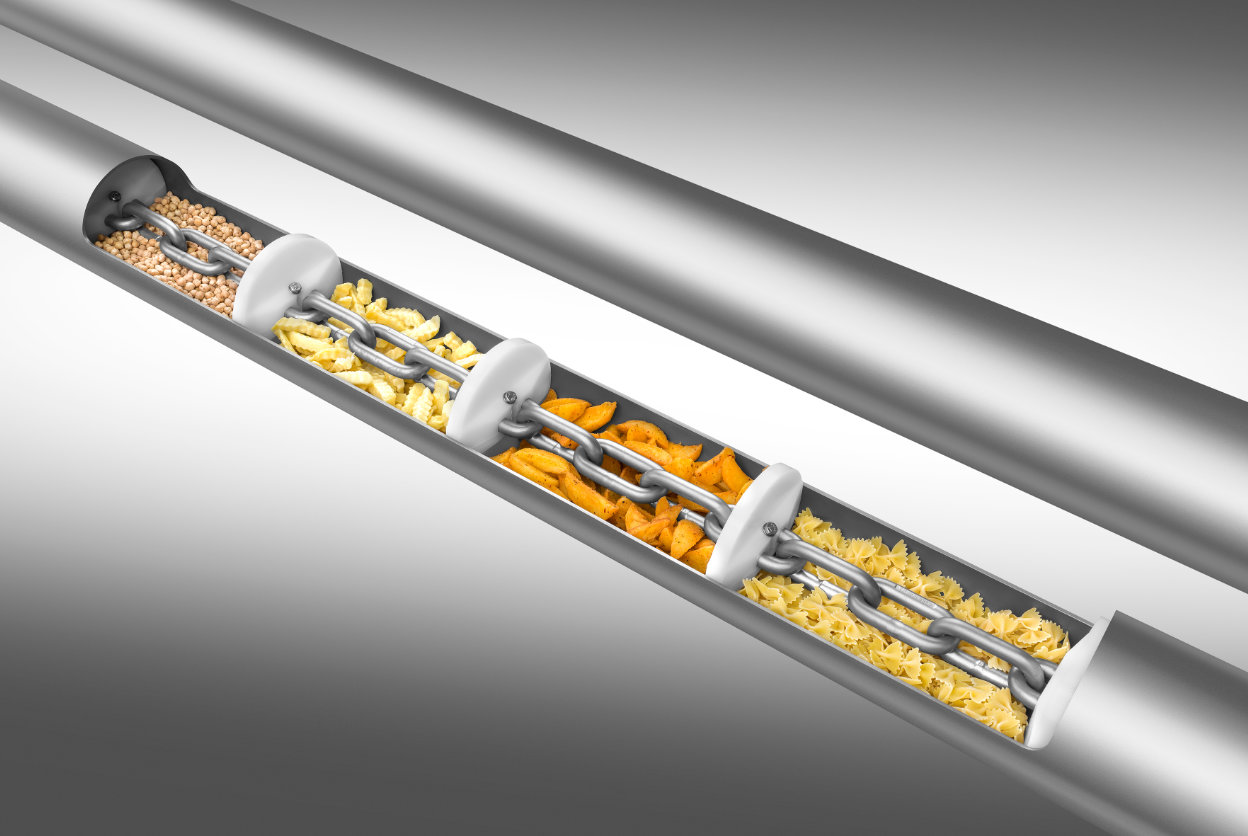

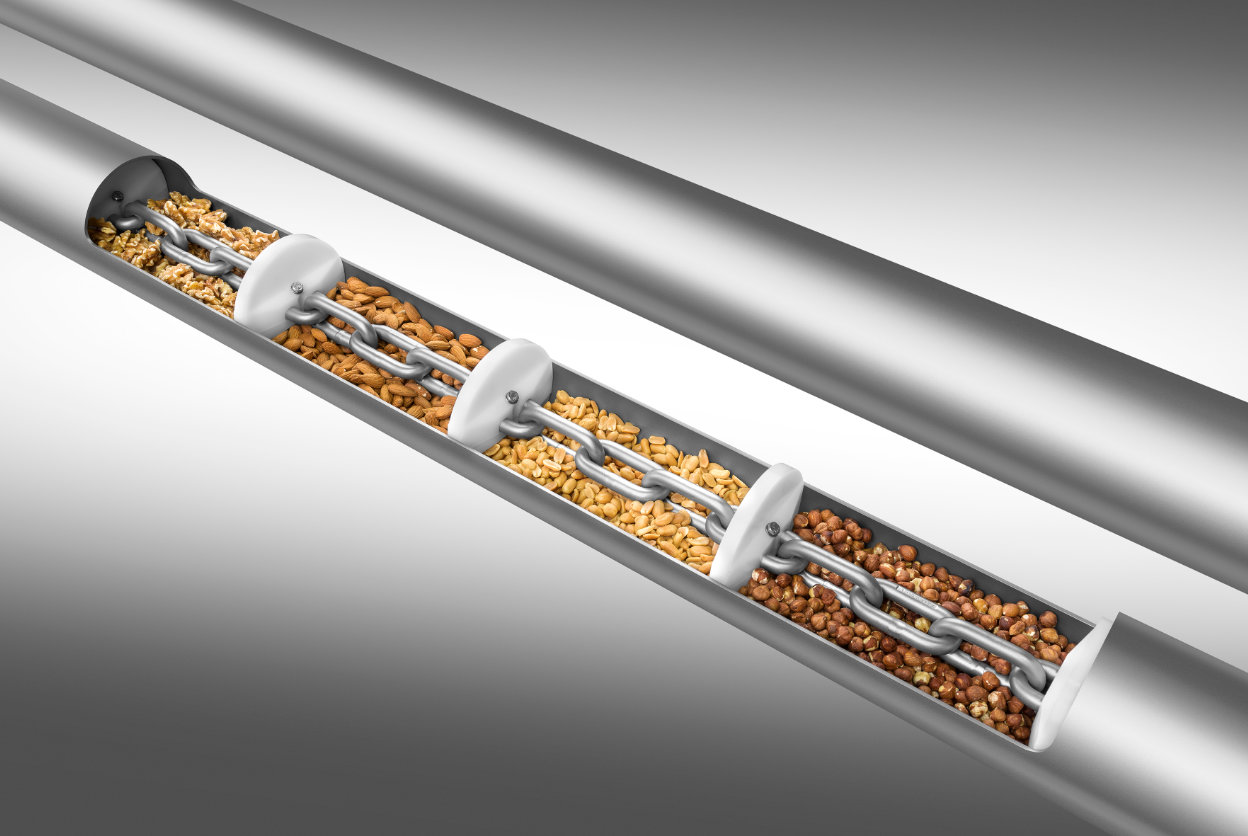

All materials used are approved by the FDA and comply with the EU Regulation governing foodstuff hygiene. Meanwhile, the corresponding systems not only feature specially designed conveyor chains, but also conveyor discs developed specifically for the food industry that prevent contamination resulting from material abrasion. In addition, using a special composition, optical foreign body sensors reliably detect foreign matter and contamination. On top of all this, we make sure to reduce harbor points and blind spots the moment we start designing our tube chain conveyors for food.

System sections that cannot be implemented without a dead spot are equipped with large access points for cleaning so as to make it possible to quickly change the material being conveyed without large-scale cleaning in between. In fact, the enclosed nature of the system makes cleaning ports easy to design and automate. Moreover, there is the option of equipping each tube chain conveyor with a selection of modules such as rotating FDA-approved brushes, directed vibrators, and targeted air jets in order to help discharge heavily glutinous and sticky materials.