Bulk material loading

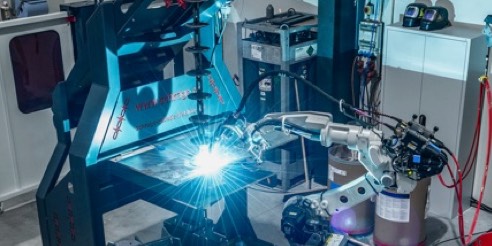

Form follows function.

Your bulk material determines not only how we’ll go about things during the design engineering stage, but also lets us know what materials we need to use. And in order to truly understand every single requirement, the first step is thorough and extensive testing at our own technical center. We’ll configure your conveyors in a manner that is tailored to your needs so that you don’t have make alterations at the setup location. Clean, gas-tight, pressure-tight, gentle on your materials, and even

operationally safe in hazardous locations thanks to optional ATEX-compliant versions – the perfect way to reliably get things done at your company. Our low-maintenance systems are not just extremely resistant to wear, but can also handle virtually any pourable bulk material. And that’s regardless of whether you’re working with dusty, granular, or coarse material – you’ll get nearly 100% residue emptying without any segregation.